Picosecond laser glass cutting machine price

Application of picosecond laser glass cutting machine

1. Strengthened and non-strengthened glass cutting, such as: mobile phone glass cover, car glass cover, camera glass cover, etc.;

2. Sapphire glass cutting, such as: mobile phone sapphire cover, camera sapphire glass cover, sapphire light bar (LED light bar), etc.;

3. LCD screen glass cutting, such as: special-shaped LCD screen inverted R/U/C angle, LCD screen cutting, etc.;

4. Other optical glass cutting, such as: filter cutting, mirror cutting, etc.

Parameters of picosecond laser

| Brand | HITEC CNC |

| Laser type | Picosecond pulse laser (seed source adopts world mainstream brands such as Nlight) |

| Power | 50W (optional 30W, 80W, etc.) |

| Wavelength | 1064nm, beam quality: M2<1.3 |

| Pulse length | <10PS; pulse frequency: 1Hz-1000kHz |

| Cooling method | Cooling method: water cooling |

| Laser cutting head | |

| Focus head | Bezier focus head |

| Number of cutting heads | single head |

| Focus spot | <2um |

| Cutting performance | |

| Cutting speed | 0-300mm/s adjustable |

| Cutting thickness | Once ≤ 12mm (different materials may affect the processing thickness, thicker ones can be cut with multiple knives) |

| Minimum cutting chipping | <5um |

| Cutting accuracy | ≤20um |

| X/Y cutting stroke | 600mm x700mm, double platform |

| Split laser source | |

| Laser type | CO2 laser source |

| Power | 80W |

| Wavelength | 10.6um |

| Pulse length | Pulse frequency: 1Hz-100kHz |

| Cooling method | Cooling method: water cooling |

| Split head | |

| Focus head | F50 focusing lens |

| Number of cutting heads | single head |

| Focus spot | 2mm (reference value 1-3mm, adjusted according to the needs of lobes) |

| Split performance | |

| Splitting speed | 0-300mm/s adjustable |

| X/Y travel | 550mm*650mm, double platform |

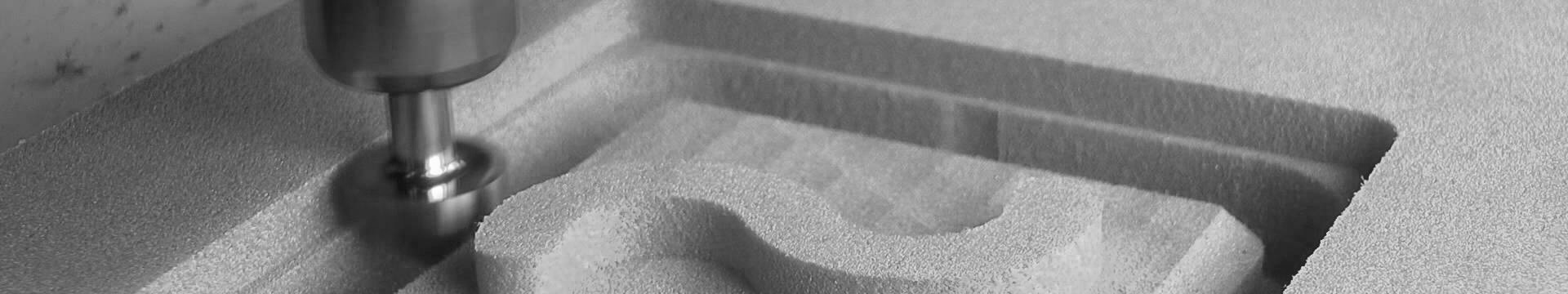

Picosecond laser head

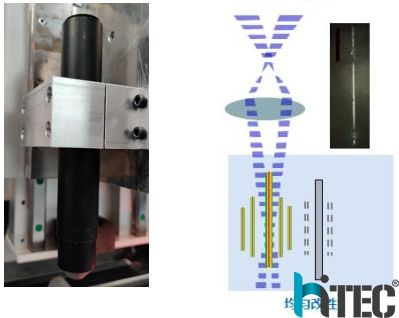

With CCD Camera

CCD positioning system, range axis and coaxial

Precise focus, precise positioning, positioning accuracy within microseconds

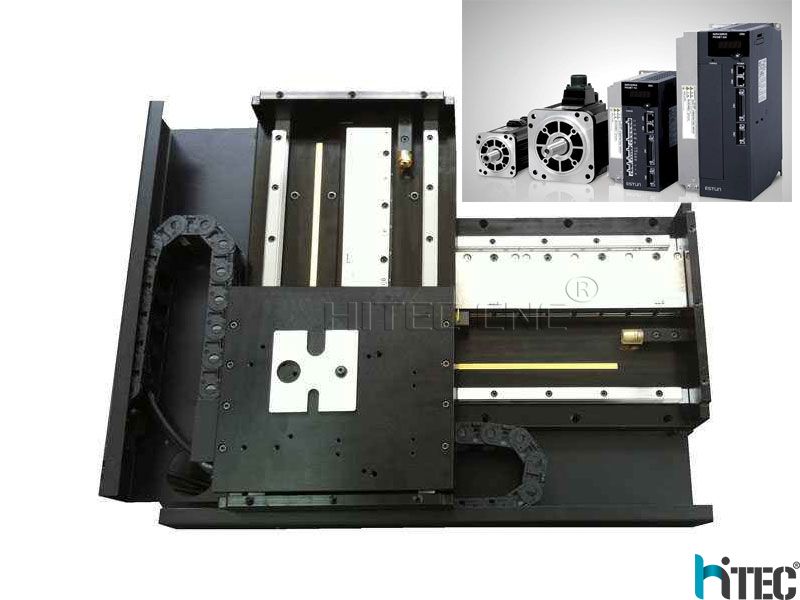

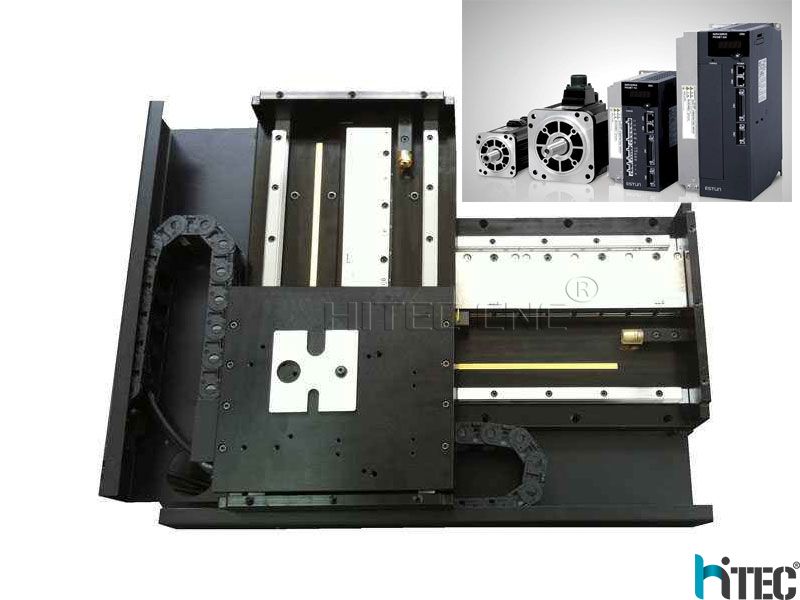

Precision motion platform

Precision motion platform

The motion platform is driven by servo motors

The platform processing range and XY positioning accuracy are mainly determined by the servo motor

The servo motor controls the rotation angle by controlling the length of the pulse time, and its rotation accuracy can reach 0.036

Servo motor is the core component of precision motion platform

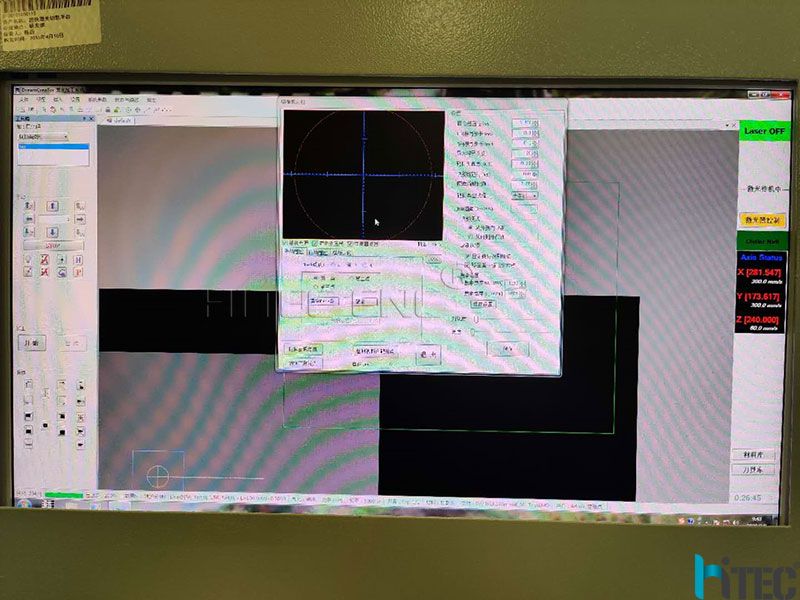

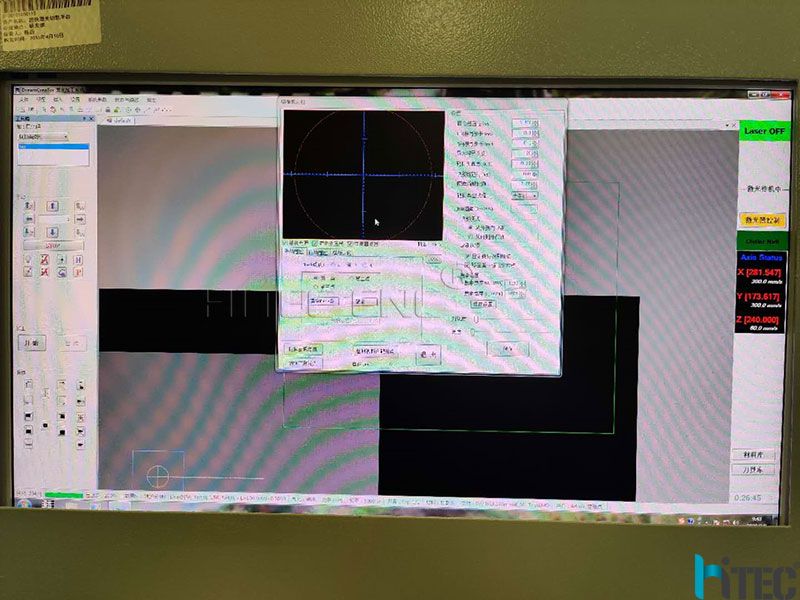

Control system

Control system

1. Control laser output

2. Control the motion platform to move in X, Y and Z directions

3. Control CCD visual MARK point positioning, focusing, and observation

4. Other functions such as POD function

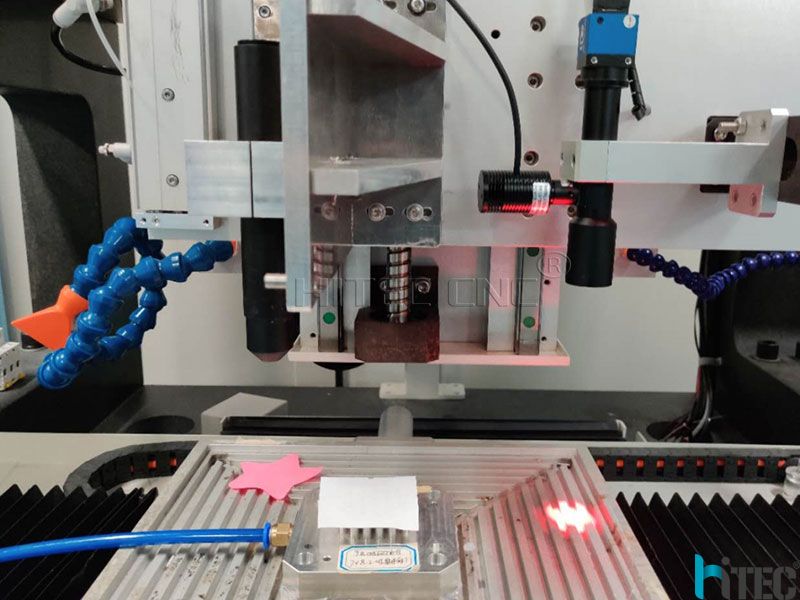

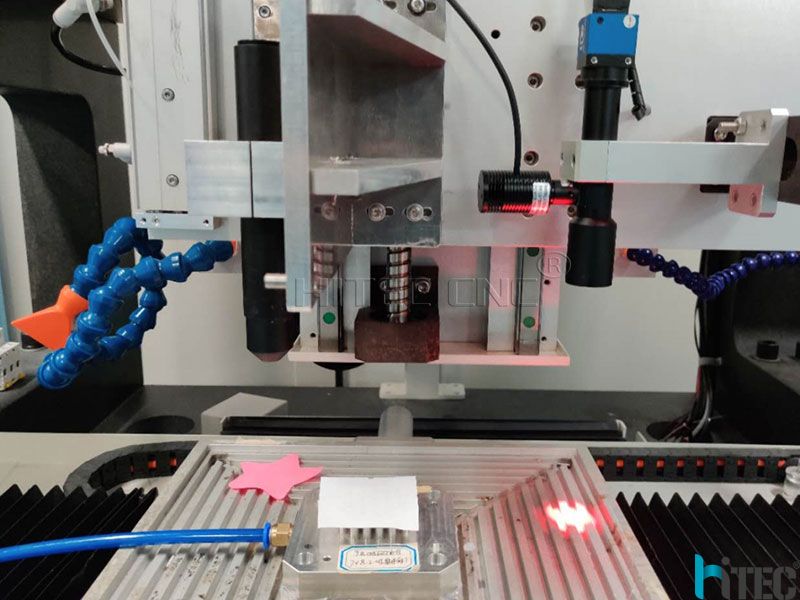

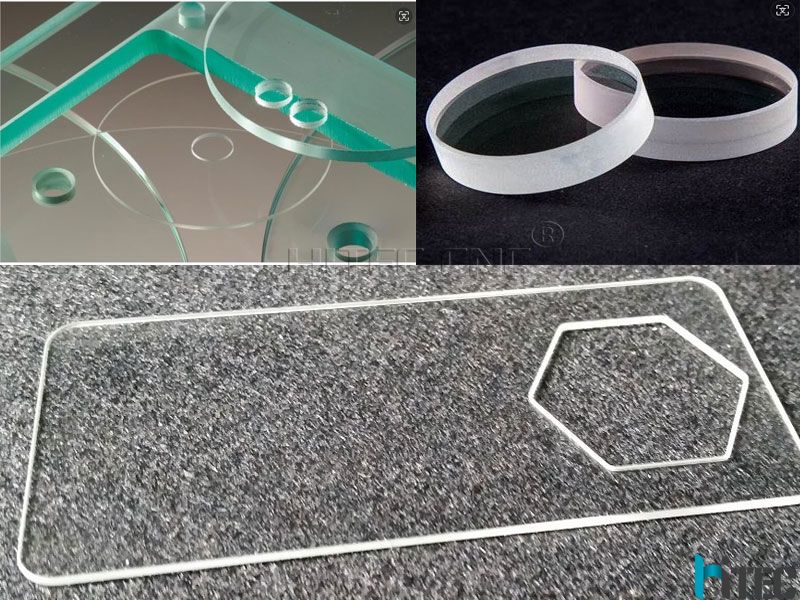

Test Samples

Tag: picosecond laser glass cutting machine glass cutting machine laser cutting machine price