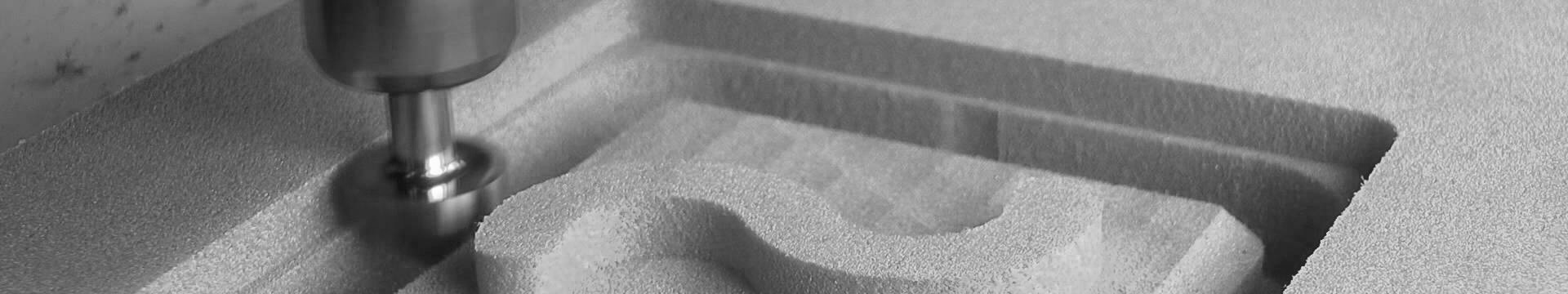

3D Deep metal laser engraving machine with EZCAD3 software

EZCAD3 works with DLC2 series laser controller, with the ability to control most types of lasers (Fiber, CO2, UV, Green, YAG, Picosecond, Femtosecond...) in the market, with brands like IPG, Coherent, Rofin, Raycus, Max Photonics, JPT, Reci, and Dawei...

As for laser galvo control, till Jan 2020, it is compatible with 2D and 3D laser galvo with XY2-100 and SL2-100 protocol, from 16 bits to 20 bits, both analogical and digital.

EZCAD3 inherits all the functions and features of EZCAD2 software and equipped with the most advanced software and laser control technologies. Now it is widely verified and adapted by global laser system manufacturers on their laser machines, which is with laser galvo.

Can we marking 3d relief design use EZCAD3?

Choose DLC controller and EZCA3 +Electri Lift can do the job.

Metal types compatible with a fiber laser machine:

Stainless SteelCan we marking 3d relief design use EZCAD3?

Choose DLC controller and EZCA3 +Electri Lift can do the job.

Metal types compatible with a fiber laser machine:

Aluminum

Titanium

Brass

Copper

Silver

Gold

Hardened Metals

Iron

Laser Engraver Features

Free maintenance and low operation cost.

Fast Speed: Imported laser scanning system makes the marking speed up to 7000mm/s.

High Precision: Re-position precision is 0.002mm.

High-Rate of Electrical-Optical Conversion: up to 70%.

Easy Operating: Easy operation, English User Manual VCD training video, software sending together with he machine.

The machine can be compatible with software files such as Coreldraw, AutoCAD, Photoshop;PLT, PCX, DXF, BMP, STL etc supported.

New Features Comparing with EZCAD2 software

1. 64 bits Software Kernel

3. Four Axis Control

5. Remote Control Via TCP IP

7. High-Speed MOF

9. Gradual Power Up/Down Control

2. STL Slicing

4. 3D Processing

6. Offline Processing

8. Software SDK/API

10. Gradual Speed Up/Down Control

Parameters

| Basic | Software | EZCAD3.0 | |

| Software Kernel | 64 bits | ||

| Operation System | Windows XP/7/10, 64 bits | ||

| Controller Structure | FPGA for laser and galvo control, DSP for data processing. | ||

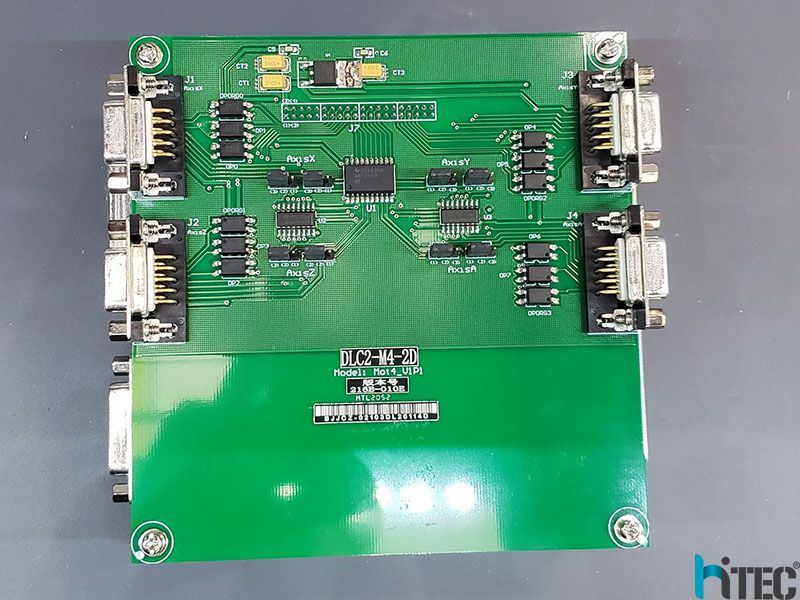

| Control | Compatible Controller | DLC2-M4-2D | DLC2-M4-3D |

| Compatible Laser | Standard: fiber Interface board for other types of laser DLC-SPI: SPI laser DLC-STD: CO2, UV, green laser... DLC-QCW5V: CW or QCW laser requires 5V control signals. DLC-QCW24V: CW or QCW laser requires 24V control signals. |

||

| Note: Lasers with some brands or models may need special control signals. A manual is needed to confirm the compatibility. |

|||

| Compatible Galvo | 2 axis galvo | 2 axis and 3 axis Galvo | |

| Standard: XY2-100 protocol Optional: SL2-100 protocol,16 bit,18 bits, and 20 bits galvo both digital and analogical. |

|||

| Extending Axis | Standard: 4 axis Control (PUL/DIR Signals) | ||

| I/O | 10 TTL Inputs, 8 TTL/OC Outputs | ||

| CAD | Filling | Background filling, annular filling, random angle filling, and cross filling. maximum 8 mixed fillings with individual parameters. |

|

| Font Type | Ture-Type font,Single-Line font,DotMatrix font,SHX font... | ||

| 1D Barcode | Code11, Code 39, EAN, UPC, PDF417... New types of 1D Barcode can be added. |

||

| 2D Barcode | Datamatix, QR Code, Micro QR Code, AZTEC CODE, GM CODE... New types of 2D Barcode can be added. |

||

| Vector File | PLT,DXF,AI,DST,SVG,GBR,NC,DST,JPC,BOT... | ||

| Bitmap File | BMP,JPG,JPEG,GIF,TGA,PNG,TIF,TIFF... | ||

| 3D File | STL, DXF... | ||

| Dynamic Content | Fixed text, date, time, keyboard Input, jump text, listed text, dynamic file data can be sent via Excel, Text file, serial port, and Ethernet port. |

||

| Other Functions | Galvo Calibration | Internal calibration, 3X3 point Calibration and Z-axis calibration. |

|

| Red Light Preview | √ | ||

| Password Control | √ | ||

| Multi-File Processing | √ | ||

| Multi-Layer Processing | √ | ||

| STL Slicing | √ | ||

| Camera Viewing | Optional | ||

| Remote Control Via TCP IP | √ | ||

| Parameter Assistant | √ | ||

| Stand Alone Function | √ | ||

| Gradual Power UP/Down | Optional | ||

| Gradual Speed UP/Down | Optional | ||

| Industrial 4.0 Laser Cloud | Optional | ||

| Software Library SDK | Optional | ||

| PSO Function | Optional | ||

| Typical Applications |

2D Laser Marking | √ | |

| Marking on The Fly | √ | ||

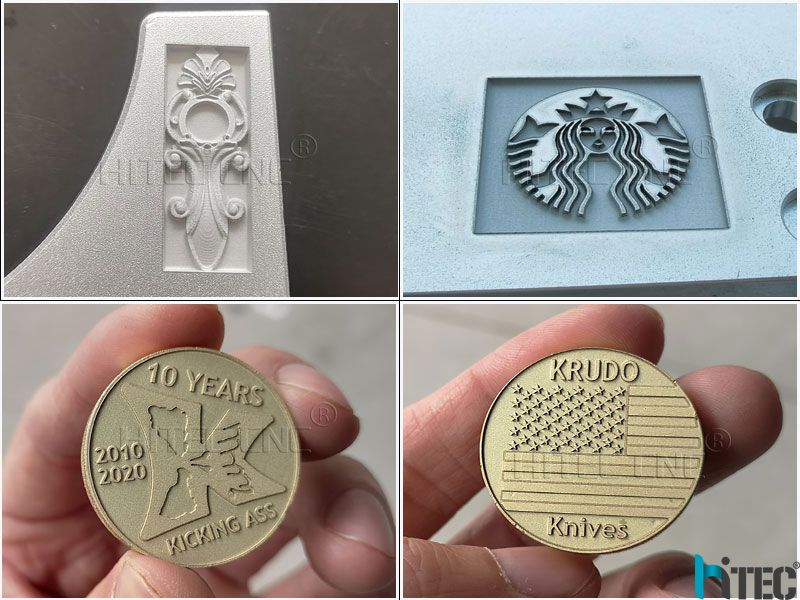

| 2.5D Deep Engraving | √ | ||

| 3D Laser Marking | √ | √ | |

| Rotary Laser Marking | √ | ||

| Split Laser Marking | √ | ||

| Laser Welding with Galvo | √ | ||

| Laser Cutting with Galvo | √ | ||

| Laser Cleaning with Galvo | √ | ||

| other laser applications with Galvo. | Please consult our sales engineers. | ||

Samples Making By our Germany Customer

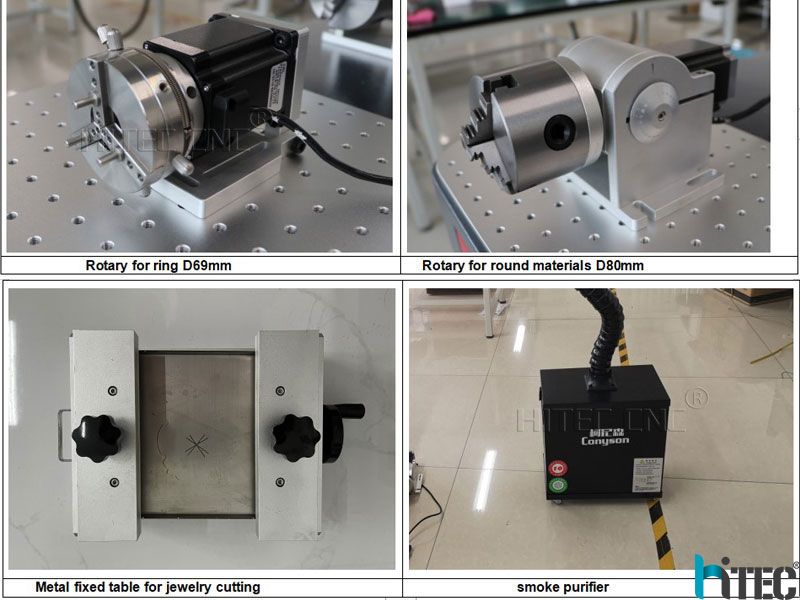

Optional Parts

Packing List

PS: Materials customer concern

ALUMINUM

For aluminum marking and traceability, laser engraving machines and systems can generate a wide range of grays (from white to black) on the surface of aluminum parts.

Etching aluminum

Marking serial numbers on aluminum billets

Engraving QR or data matrix codes on sows, ingots or die-cast parts

Etching logos on aluminum sheets or pieces

Marking anodized aluminum by selectively removing its coating

STEEL

Steel is a hard material that requires longer marking times than other metals. However, the marking speed can be increased by creating white marks instead of black ones. White marks contrast well with the bare steel color for most steel types.

For high-speed marking, laser etching is the best process for steel surfaces. To get the most resistant marks, laser engraving should be used. To increase corrosion resistance, laser annealing creates marks under the surface. You can laser mark any steel alloy, including anodized steel, carbon steel and die steel.

Steel parts: suspension springs, brake pads, coils, billets, plates, pipes, tubes, sheet steel, and more

STAINLESS STEEL

Laser marking is most often used to mark stainless steel grades 304 and 316, but it can be used to mark any grade. The preferred marking method for stainless steel is laser annealing since it protects the chromium oxide layer on the metal surface. As a result, you get high-quality marks and prevent the formation of rust on the surface.

Stainless steel doesn’t require a high-power laser. This is because laser annealing works at lower energy levels than other marking processes.

Stainless steel parts: Fuel tanks, exhausts, suspensions, and other automotive parts

ZINC

Zinc is not only used for its corrosion resistance, but also for its ability to be die casted. Laser etching is the only laser marking process that generates a high contrast on zinc parts. It can be used regardless of the zinc alloy.

Zinc part examples: ingot bundles, jumbo blocks, die cast ingots, anode ingots, slabs, die castings, automotive parts, and more

STAINLESS STEEL

Laser marking is most often used to mark stainless steel grades 304 and 316, but it can be used to mark any grade. The preferred marking method for stainless steel is laser annealing since it protects the chromium oxide layer on the metal surface. As a result, you get high-quality marks and prevent the formation of rust on the surface.

Stainless steel doesn’t require a high-power laser. This is because laser annealing works at lower energy levels than other marking processes.

Stainless steel parts: Fuel tanks, exhausts, suspensions, and other automotive parts

ZINC

Zinc is not only used for its corrosion resistance, but also for its ability to be die casted. Laser etching is the only laser marking process that generates a high contrast on zinc parts. It can be used regardless of the zinc alloy.

Zinc part examples: ingot bundles, jumbo blocks, die cast ingots, anode ingots, slabs, die castings, automotive parts, and more

Tag: deep metal laser engraving machine laser engraving machine metal engraving laser engraving machine with ezcad3 ezcad3 software