cnc wood lathe double axis

cnc wood lathe double axis application

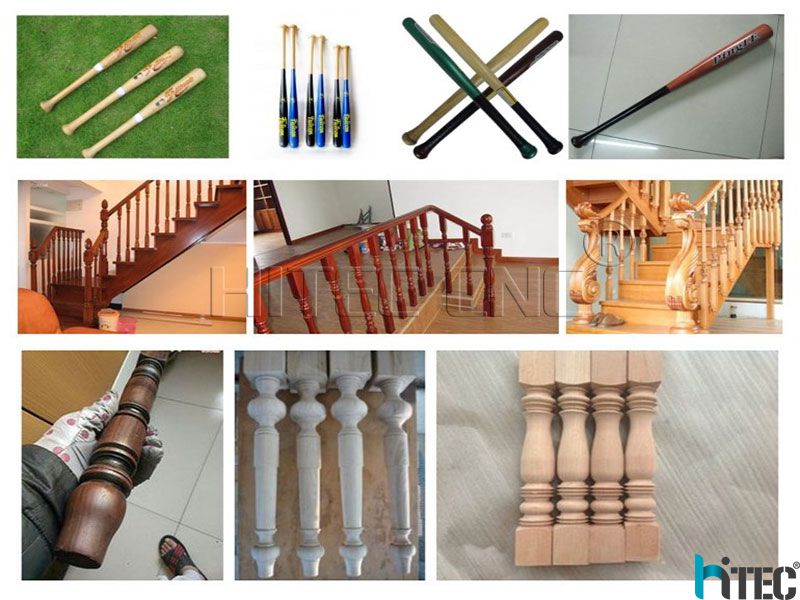

CNC wood turning lathe machine is designed for cylindrical or conoid work pieces, milling for circular staircase stingers, for example pillar, banister, chair legs, staircases, stairway balusters, stairway newel posts; dining table legs; end table legs; sofa table legs; bar stool legs; chair legs; chair arm posts; chair stretchers; bed rails; lamp posts; baseball bats and so on.

Features of cnc wood lathe double axis

1). It is a very precise, efficient CNC wood turning lathe with first-class workmanship.

2). Operating system: Friendly simple operation interface, English suggestion and simple setting method.

3). Motor System: domestic famous brand stepper motor to ensure the precision.

4). Transmission System: Hiwin square rail and ball screw to control the linear error effectively.

5). Inverter System: Adopts import inverter system to adjust the rotation speed and solve the vibration problem of timber.

6). Rotary System: Divided into the single axial and biaxial, the chuck can be mounted to the system and biaxial can produce two pieces at the same time.

7). Single sided carbide blades for simple blade replacement.

8). Structure: heavy steel construction to avoid vibration, processed surface is smooth and precision.

9). Infinitely variable DC feed motor with feeding speed of 0 to 3600rpm.

10). The wood CNC lathe use DSP handle control system. Controlled offline, use USB to load G code. Easy to operate.

cnc wood lathe double axis Standard configuration

1,12 inch color screen, built-in CNC computer;

2, imported linear guide, precision ball screws;

3, engraving spindle and pull trough multifunction control section;

4, universal swivel joints;

5, the rotation center with the knife (5CM ~ 6CM wooden);

6, pneumatic feeding, automatic centering;

7, pneumatic material thimble;

8, V-type front steel tools;

9, with controls easy to use software, the basic pattern software;

10 randomly accompanied.

Select Configure

1, φ160 four jaw chuck linkage;

2, woodworking special vacuum cleaner;

3,220V constant power frequency spindle control;

Paramaters

| Model | HTL1530-2Axis wood turning lathe machine for stairs |

| Working area | 1500mm(length)*300mm (diameter) when one spindle work |

| Whole Machine | Stable and low inertia |

| Spindle motor | Stepper motor, 4KW frequency spindle |

| Inverter motor | Berglah(high-end brand)High-precision motor drive, through the program calculates, can ensure the accuracy of processing |

| Feeding parts | Combined high-quality rails with precise screw drive , effective control error |

| Working speed | 5X60cm Standard staircase column 40S/one |

| voltage | 380V 220V |

| cutter | 2 white steel blades (18x18x200mm), 2 Korea imported alloy blades |

| Auxiliary hardware and software | Turning center with the knife (5cm wood, 6cm wood) tail top pin manual stretching, combined with pneumatic, convenient and flexible, intelligent protection work table (limit alarm system) to prevent the collision phenomenon |

| Control system | Original DSP control system |

| Software supported | TYPE3/ARTCAM/UCANCAM/CAXA/MASTERCAM/Other software output code |

wood lathe turning machine samples

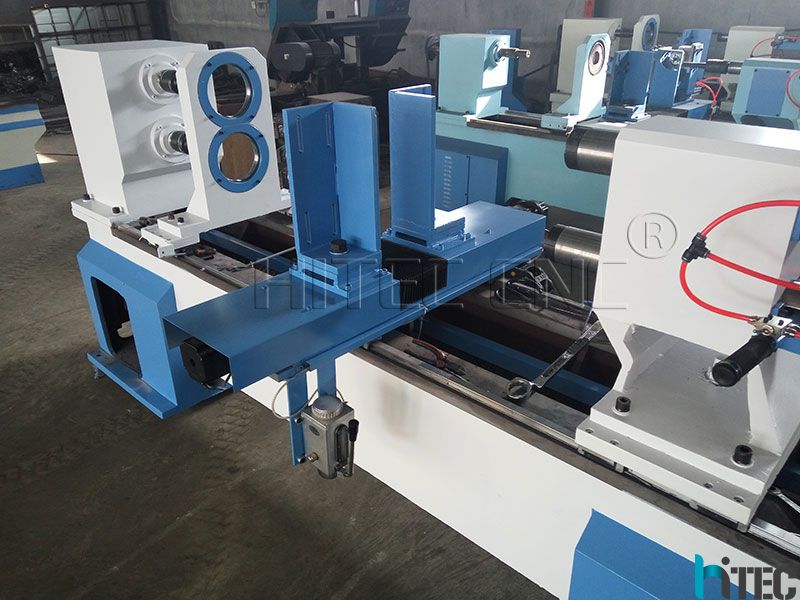

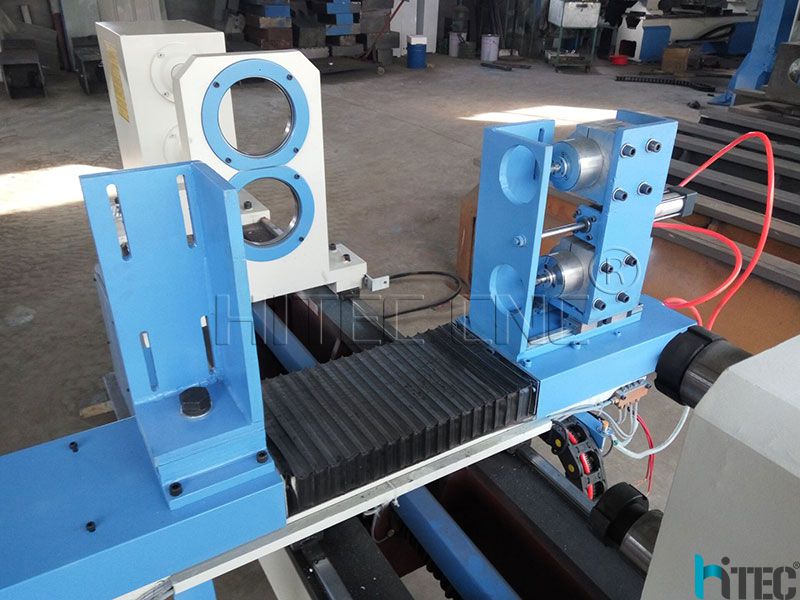

wood lathe turning machine details parts

Our Hitec after sales and guatantee details

Before sale:

We would always be here to provide any information you need at the first time,and give professional suggestions according to your real needs for free.

During sale:

We would deal with all the production and shipping affairs,after everything is ready,we would tell you everything goes well here.

After sale:

We would provide English Version working manual.

If you have any questions during using and maintaining,our engineers who could speak very good english would answer you online or by calls.

Machine warranty is one year.So if your machine has any unintentional damages,we would provide parts for free.

If your machine has big problems if by any chance,our engineers would arrive there to debug and fix.

our professional after sale service team which are selected by very strict examinations,would pay their 100% time and energy to solve your problems.

Tag: wood lathe machine cnc wood lathe machine wood turning machine cnc stairs wood lathe machine