Customize Size 3660 Auto Feeding Cutting Table Cloth Textile Cutter For Automatic Fabric Cutting Machine CNC Cut Fabric

Application of auto feeding cloth textile cutter

The Cutting Machine is widely used in industrial leather, plastic, rubber, sponge, foam, EVA, PVC, cardboard, paper products, fabric, home textiles, packaging materials, non-woven, carpet, car cushion, felt, synthetic materials, and other non-metallic materials in various industries; Extremely suitable for cutting multiple layers of material at one time, etc.

Parameters

| Model No. | HTO1625 | HTO2025 | HTO2325 |

| Cutting area (W*L) | 1600*2500mm | 2000*2500mm | 2300*2500mm |

| Cutting thickness | Max.70mm (vacuum suction) | ||

| Cutting materials | Garment cloth(knitted and woven), no-woven fabric, plush toys, shoes, leather, sofa cushion, car interior decorative fabric, bars, medical gauze, composite fabric, ect. |

||

| Max cutting speed | 60m/min (according cutting materials) | ||

| Cutting accuracy | ≤±1mm | ||

| Power | 16-25kw | ||

| Cutting style | Straight Knife Continuous Up-down Cutting | ||

| Cooling system | Auto Air Cooling System | ||

| Control System | compatibilty with any version CAD software | ||

| Software | Multi-language ACS software, auto change | ||

| Sharpen way | Double gear derogatory method | ||

| Air pressure supply | 7KPS | ||

| Max speed | 4000rpm/min | ||

| Motor/Driver | Japanese Panosonic Servo motors & Drivers | ||

| Machine power | AC380V/50HZ | ||

| Machine out size (mm) | 5900*2650*1500 | 5900*2950*1500 | 5900*3250*1500 |

Advantage of CNC Fabric Cutter

HITEC offers cutting room automation and solutions that can significantly improve efficiency and productivity in the textile industry. Here are some key features and advantages of Dematron cutting room automation:

1. Automated Cutting Systems: HITEC provides fully automated cutting systems that integrate cutting machines, material handling systems, and software solutions. These systems can handle the entire cutting process, from fabric spreading to cutting and sorting. This automation reduces the need for manual labor and streamlines the production flow.

2. Material Spreading Solutions: HITEC offers automated fabric spreading solutions that ensure accurate and efficient material placement. These systems can handle various fabric types and sizes, optimizing material usage and reducing waste. Automated spreading also eliminates the risk of human error, ensuring consistent quality and precision.

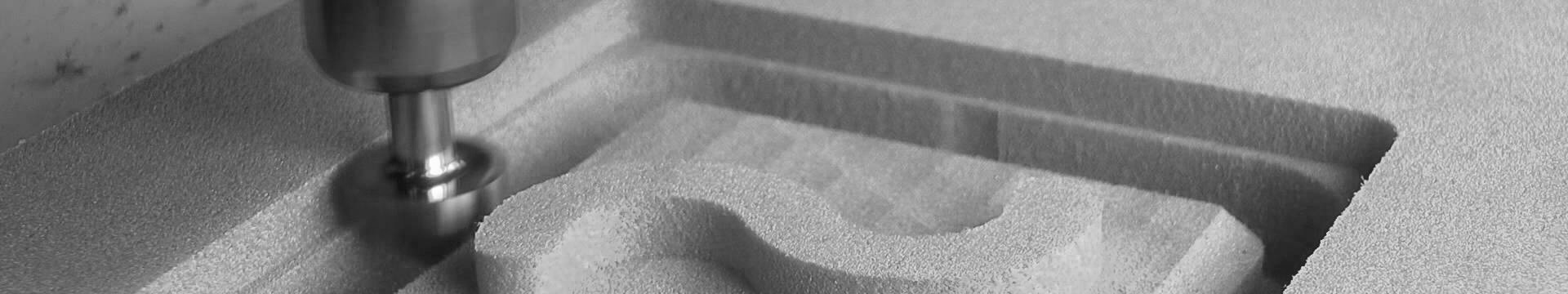

3. CNC Cutting Machines: HITEC CNC cutting machines are equipped with advanced technology that allows for precise and high-speed cutting. These machines can handle multiple layers of fabric simultaneously, increasing productivity and reducing cutting time. The CNC technology ensures accuracy and consistency in cutting patterns, resulting in high-quality finished products.

4. Nesting Software:HITEC provides intelligent nesting software that optimizes material usage and reduces wastage. The software analyzes cutting patterns and arranges them in the most efficient way, minimizing the amount of fabric required. This optimization not only saves costs but also reduces environmental impact.

Cutting Effects

1.Accurate

The cutting machine meets the cutting precision: 0.3mm to 0.5mm.

2. Delicacy

With our cutting machine for garment making, you can easily meet the market needs for customized cloth,

garment or designs.

3.Multi-layer

This garment plotter can cut several layers materials, and very suitable for some customized production.

4.Smooth

The Oscillating Cutting Tool assures our cutting machines cut smoothly. And this cutting effects can hardly be done by laser cutting machine, die cutter or manual workers.

HITEC CNC Digital Cutter Factory

HITEC CNC Digital Cutter Factory

Tag: fabric cutter machine cloth cutting machine textile cutter machine cnc digital cutter