- Home

- About HITEC

- Products

- Samples

- Service and Support

- News

- Contact HITEC

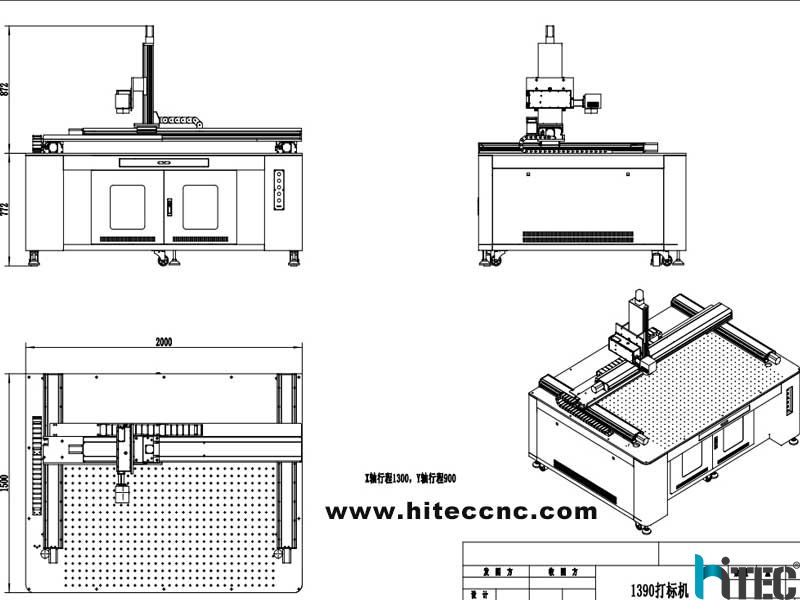

In the laser marking industry, efficiency, precision, and flexibility define success. One advanced upgrade that delivers all three is the XY moving table. When paired with a laser marking machine, it transforms the way you handle large-size marking, batch production, and high-precision engraving.

A fixed laser head has a limited working area. With an XY moving table, your marking area expands beyond standard boundaries.

Perfect for large metal sheets

Ideal for oversized logos and signage

Suitable for industrial nameplates

The table moves in both X and Y directions, allowing the laser to cover every section without manual repositioning.

The XY motion platform is driven by high-accuracy servo or stepper motors. This ensures:

Micron-level accuracy

Consistent engraving quality across the entire surface

Perfect alignment for multi-pass or deep engraving

Industries like aerospace, electronics, and medical devices benefit from this precision.

With the XY moving table, you can fix multiple parts on a jig and let the machine mark them one by one automatically.

Advantages include:

Faster production cycles

No manual repositioning

Lower labor costs

Jewelry makers, tool manufacturers, and electronics companies rely on this method for high-volume orders.

An XY moving table works with:

UV laser marking machines – for ultra-fine, heat-sensitive materials

This flexibility is perfect for businesses serving multiple industries.

Your XY moving table laser marking machine can be upgraded with:

Automated loading/unloading

Conveyor belt systems

Vision positioning systems for perfect alignment

This creates a fully automated laser marking solution, reducing errors and saving labor.

If you need large-format laser marking, multi-piece engraving, or high-precision results, an XY moving table is the smart choice.

By integrating it with your laser marking machine, you achieve faster production, better quality, and higher efficiency—a must-have for modern manufacturing.