- Home

- About HITEC

- Products

- Samples

- Service and Support

- News

- Contact HITEC

Many manufacturers still rely on ink printing, labels, stamping, or mechanical engraving. These methods present several long‑term problems:

Ink markings fade, smear, or peel during storage and transportation

Labels fall off or become unreadable in outdoor environments

Mechanical engraving damages the zinc coating and causes rust

Stamping deforms thin galvanized sheets

High consumable cost and frequent maintenance

These issues directly affect product quality, traceability compliance, and customer trust.

Fiber Laser Marking: The Best Solution for Black Sheet Galvanized Steel

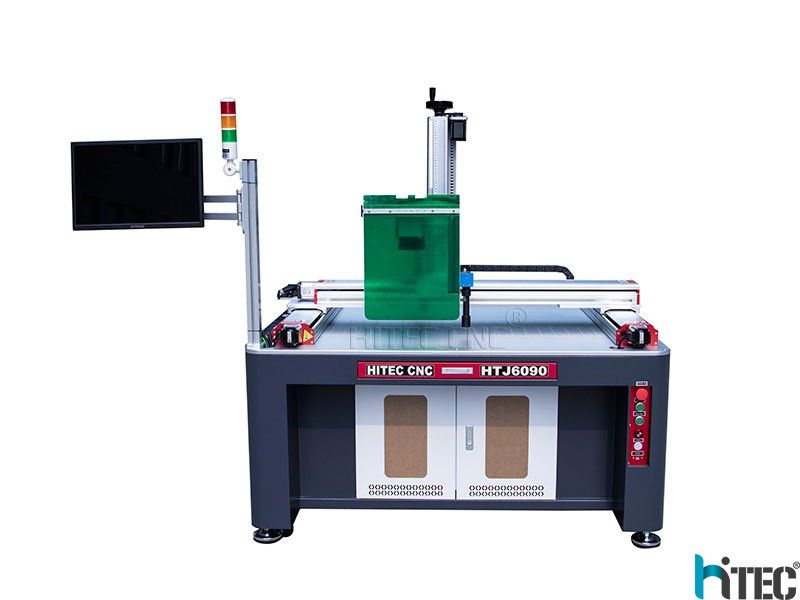

Fiber laser marking machines provide a non‑contact, coating‑safe, and permanent marking solution for galvanized black sheets.

Unlike engraving, fiber laser marking uses precisely controlled laser energy to create high‑contrast surface marks through micro‑oxidation or color change, without penetrating or removing the zinc layer.

This makes it ideal for marking zinc‑coated steel while preserving corrosion resistance.

The laser interacts with the surface coating only

No physical contact or mechanical stress

No consumables such as ink or chemicals

Minimal heat input, no sheet deformation

The result is a clean, dark, and permanent mark that remains readable after bending, welding, painting, or outdoor exposure.

1. Protects Zinc Coating

The marking process does not damage the galvanized layer, preventing corrosion and extending product lifespan.

2. High Contrast & Permanent Readability

Produces clear black or dark gray marks suitable for:

QR codes

Barcodes

Serial numbers

Batch and heat numbers

Logos and compliance markings

Fiber laser systems can be easily integrated into:

Coil processing lines

Sheet handling conveyors

Robotic production cells

PLC‑controlled manufacturing systems

4. Zero Consumables, Low Operating Cost

No ink, no labels, and no tooling replacement significantly reduce long‑term operating expenses.

5. Stable Quality and High Speed

Consistent marking quality with high processing speed meets mass production requirements.

Typical Applications in the Galvanized Steel Industry

Black sheet galvanized ID marking

Production date and batch code marking

QR code traceability for smart factories

Brand logo marking on finished sheets

Compliance and certification marking

1. For most black sheet galvanized applications, the following configuration is recommended:

2. Laser Type: Fiber laser

3. Power Range: 20W–500W (depending on line speed)

Manufacturers adopting fiber laser marking technology report:

Improved traceability and compliance

Reduced scrap and rework rates

Lower maintenance and operating costs

Better consistency across production batches

As regulations and quality standards continue to rise, laser marking is no longer optional—it is becoming a requirement for galvanized steel processing.